Specification: 1Cr18Ni9Ti, Magnetic seal, High pressure and temperature

|

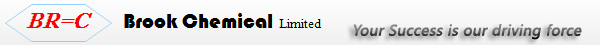

Laboratory Reactors (Magnetic Seal BCR Series) |

|||||||||||||||

| Description | BCR series high pressure reactors adopt drivers that couple with ring rare permanent magnetism. It's characteristics are high mixing torque and perfect airproof. The reactor part that contact reacting materials use 1Cr18Ni9Ti stainless steel. TA2,PTFE and Ni6 can be choices in customized production. Adopt self-lubricated wearable bearing sleeve in stirring bearing, which fit for stirring in various media. Two discharging methods, upper discharging and down discharging, for customers' selection. | ||||||||||||||

| Model | BCR-0.5 | BCR-1 | BCR-2 | BCR-3 | BCR-5 | ||||||||||

| Nominal Volume L | 0.5 | 1 | 2 | 3 | 5 | ||||||||||

| Working Pressure MPa | 15 | 20 | 30 | 15 | 20 | 30 | 15 | 20 | 30 | 15 | 20 | 30 | 15 | 20 | 30 |

| Working Temperature℃ | 300 | 300 | 300 | 300 | 300 | ||||||||||

| Stirring Rotate Speed r/min | 0-750 | 0-750 | 0-750 | 0-750 | 0-750 | ||||||||||

| Motor Power W | 123 | 123 | 123 | 123 | 400 | ||||||||||

| Heating Power KW | 1 | 1.5 | 2 | 2.5 | 3 | ||||||||||

| Controller | Equiped with automatic temperature adjuster, temperature control within ±1℃, rotate speed display and stepless timing, adjustable heating power, realize automatic temperature preservation. | ||||||||||||||

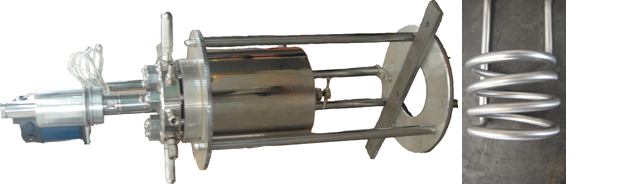

| Remark | 0.1~0.25L without inside cooling coiled pipe, 0.1~0.5L without solid charging entrance. Normal reactor using pressure 10Mpa, stirring rotate speed 0~1500r/min adjustable, working temperature 300℃, main contact material 1Gr18Ni9Ti stainless steel, push type stirring blade, ordinary DC motor; Normal reactor hatch: gas hatch match of needle valve, liquid hatch equipped with needle valve and pipe inserted reactor bottom, solid charging hatch equipped with screw plug, platinum resistance for temperature testing and control hatch, pressure meter and secure explosion-proof equipment for pressure meter safe blasting hatch, water nozzle for inside and outside entrance in reactor. We are able to customize processing and manufactuing other assistant devices (such as condensate return device, constant pressure feeding tank, receiving device, condenser and so on.) according to customers' needs. | ||||||||||||||